so far the totals for the project go like this:

$228 for tools

$415 for materials, of which $285 is fiberglass and epoxy

$643 total (but i will need more epoxy and some miscellaneous parts, so i figure about $80 more to finish, bringing my projected total to $723)

3 hours making stands and hull cradles

3 hours cutting forms

3 hours making box-beam strong back and setting forms

5 hours ripping strips

15 hours to strip the hull

22 hours to strip the deck

1 hour of pulling staples

13 hours of sanding and planing

1.5 hours making the front and rear stems

5 hours making cockpit and recess

4 hours making and epoxying the foot braces

6.5 hours of fiber glass and epoxy of deck and hull (so far...i still have the insides to do, and joining the deck and hull, and the end pours)

total time: 82 hours (all times are approximate)

i should come in under 100 for the whole project. not bad :D

Saturday, August 16, 2008

Friday, August 15, 2008

back on the forms

i wont be able to work on the 'yak for a couple of weeks, while i will be on vacation (pics when i get back :P ) so i put the whole thing back on the forms, and strapped it down tight to make sure it keeps it's shape while i am gone. i would hate to come home and find that the humidity warped it all out of whack.

it really looks like a boat when the two pieces come together. i don't have too much left to do before i get to that step for real (i wanted to finish before i left for vacation, but i ran out of time), just glassing the inside, and cutting hatches. after that its just joining the halves, making a seat (still not sure what i will do for this...i might just order a foam seat for now) and fill coats of epoxy. then a couple coats of varnish and into the water we go!

Tuesday, August 12, 2008

sanding, scraping, sanding, scraping....

took the hull off the forms over the weekend. its nice and light. now its just a matter of sanding and scraping untill its smooth enuf for a sealer coat of epoxy. i will probably mix up a batch of epoxy and wood flour (fine sanding dust) and fill some of the more un-even spots rather than trying to sand it all out. for the most part the inside can be kind of ugly, as no one will ever see it, except thru the hatches and cockpit...but i still want it to look as good as i can get it...so i sand, scrape, sand, scrape, sand, scrape...

no pics for you!

no pics for you!

Sunday, August 10, 2008

the Hull

Friday, August 8, 2008

Monday, August 4, 2008

Saturday, August 2, 2008

cockpit

i worked on the cockpit for a few hours yesterday, and again this morning. here you see the partial recess, and "keystones" of dark cedar against white pine to mimic the front sunburst.

i worked on the cockpit for a few hours yesterday, and again this morning. here you see the partial recess, and "keystones" of dark cedar against white pine to mimic the front sunburst. here you see the rear keystones in contrasting color to the front.

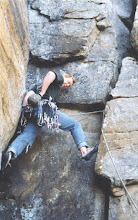

here you see the rear keystones in contrasting color to the front. i am thinking of using this climbing rope for the combing lip, grab loops and deck rigging.

i am thinking of using this climbing rope for the combing lip, grab loops and deck rigging.

Subscribe to:

Posts (Atom)